At ARICANLI, we build interactive simulation environments that replicate real machines, control systems, and production workflows so operators, engineers, and maintenance teams can train, test, and learn without risk. Using our KUDAY platform, we create accurate digital twins of PLC-controlled systems - complete with HMI interfaces, logic behavior, alarm handling, and process dynamics. These simulations run independently of physical equipment, enabling safe experimentation and repeatable learning. No downtime. No danger. Just realistic practice.

Training Models

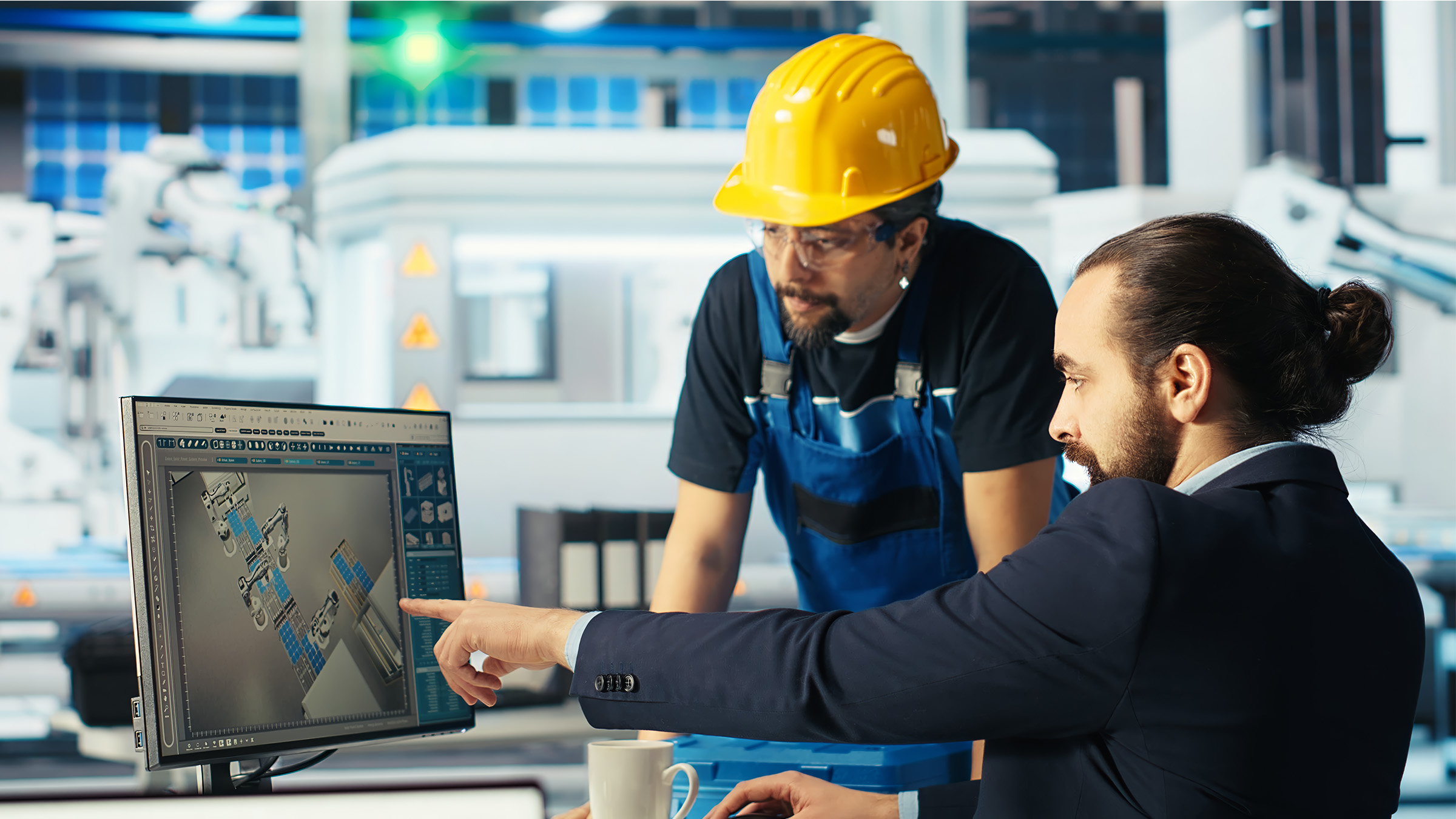

Training shouldn't be one-size-fits-all. That's why we offer multiple training models tailored to your team's needs - from new operators to experienced engineers. Whether it's self-guided learning or instructor-led drills, our simulations support different delivery styles to maximize engagement and retention. We design programs that progress from introductory operation to advanced troubleshooting, ensuring consistent knowledge transfer across shifts and roles. All built on accurate digital replicas of your actual machines and processes.

KUDAY Digital Twin Module

Every simulation starts with precision. We develop a dedicated KUDAY Digital Twin Module - a custom satellite module that mirrors the exact behavior of your PLC-controlled machine or production line. This module replicates real-time logic, I/O signals, HMI interactions, and process dynamics - so your team can interact with a 1:1 virtual version of their equipment. Once created, the module runs independently on PCs, tablets, or HMI panels - making it easy to deploy anywhere.

Training Scenario Editor

Knowing what to do in a crisis comes from experience - but you don't have to wait for a real failure to gain it. With our Training Scenario Editor, trainers and engineers can create, manage, and run custom fault scenarios within the simulation environment. Scenarios can be triggered manually or scheduled, then used in sessions to test response times, decision-making, and recovery procedures. Afterward, replay the session for coaching, analysis, and improvement tracking. It turns passive training into active problem-solving - building confidence before going live.

Ready to virtualize your processes and systems?

We understand that not all training needs are the same. That's why we offer adaptable learning models designed to fit different roles, experience levels, and operational demands. Whether it's a new operator learning basic machine control or an engineer mastering advanced troubleshooting, our simulation-based training environments provide safe, repeatable, and measurable practice. Built on accurate digital twins of real machines and processes, our training programs eliminate the risk of learning on live equipment while ensuring high engagement and knowledge retention. From self-guided modules to instructor-led drills, every path is structured to build confidence, improve response times, and reduce human error in real-world operations.

Why It Matters?

In industrial environments, mistakes made during operation can lead to downtime, safety risks, or product defects. Yet many companies still rely on on-the-job learning - where new hires learn by doing, often under pressure. Our training models change that by giving teams a risk-free environment to gain hands-on experience before they ever touch a real machine. This leads to faster ramp-up times, fewer errors, and stronger operational consistency across shifts. When every employee is trained the same way, performance becomes predictable — and excellence becomes standard.

The KUDAY Digital Twin Module is a custom-built satellite module that replicates the exact behavior of your PLC-controlled equipment, creating a 1:1 virtual twin for training, testing, and troubleshooting. Unlike generic simulators, our digital twins are based on real PLC logic, tag structures, I/O configurations, and process dynamics. This means operators train on what feels like the actual machine - without risking downtime or safety. Whether it's a tire curing press, a tunnel ventilation system, or a naval engine room interface, we build dedicated modules that run within the KUDAY ecosystem - so your team can learn, experiment, and improve in a risk-free environment. No guesswork. No compromises. Just realistic, reliable simulation.

Why It Matters?

In industries where precision and safety are critical, learning on live equipment carries real risk. A misstep during training can lead to downtime, damaged tools, or even injury. With the KUDAY Digital Twin Module, teams gain hands-on experience in a safe, repeatable environment - building muscle memory and confidence before ever touching the real machine. These modules are already used by the Turkish Naval Forces for crew readiness on warships - proving their reliability under mission-critical conditions. Now, the same technology is available for manufacturing, infrastructure, and OEMs who want to future-proof their operations through intelligent simulation.

In high-pressure industrial environments, how teams respond to emergencies, faults, or process deviations can mean the difference between a quick recovery and costly downtime. At ARICANLI, we give you the tools to prepare - with our Training Scenario Editor, a powerful interface that lets trainers and engineers design, manage, and run custom simulation scenarios within the KUDAY digital twin environment. Instead of relying on memory or theoretical training, your team can experience real-world challenges in a safe, repeatable way. From sensor failures to communication loss, you define what happens - then test how operators react. Whether it's for onboarding, certification, or continuous improvement, our scenario-based approach turns passive learning into active problem-solving.

Why It Matters?

In industries like manufacturing, marine, and infrastructure, the best time to learn how to handle a crisis is before it happens. Yet most training relies on static manuals or one-time walkthroughs - leaving gaps in preparedness. With the Training Scenario Editor, teams gain hands-on experience in a risk-free environment, building muscle memory and confidence through repetition. This isn't just about fixing machines - it's about improving decision-making under pressure. By practicing realistic scenarios, operators become faster, more accurate, and less likely to make errors when real incidents occur.