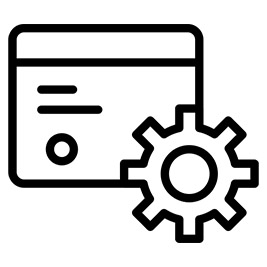

A Module for Every Platform and Protocol

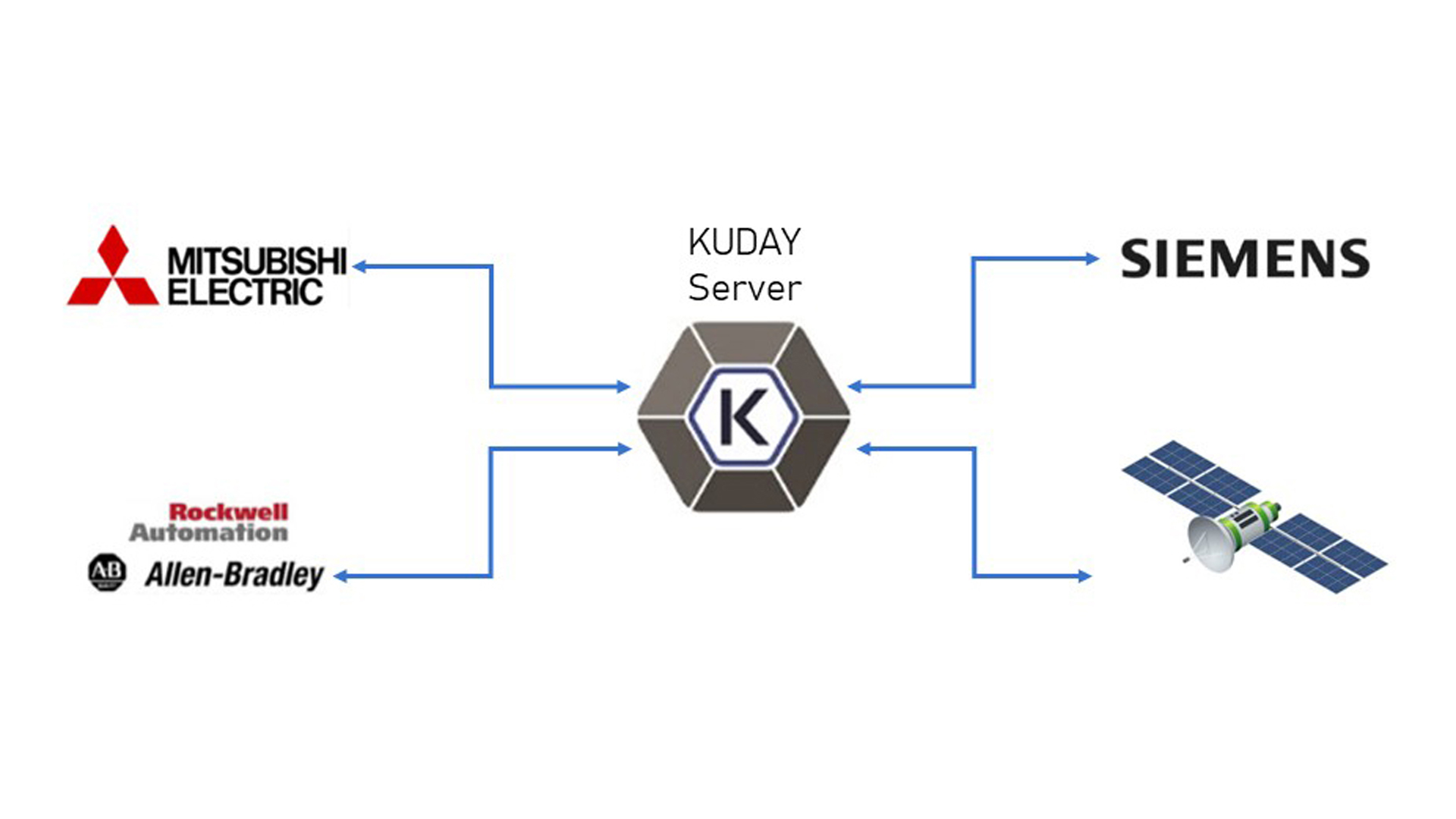

The KUDAY platform grows with your needs.

Our ever-expanding library of modular software components ensures seamless connectivity across machines, protocols, and systems - now and into the future.

Built in-house and refined through real-world industrial challenges, new modules are continuously developed to meet emerging demands and custom integration requests.

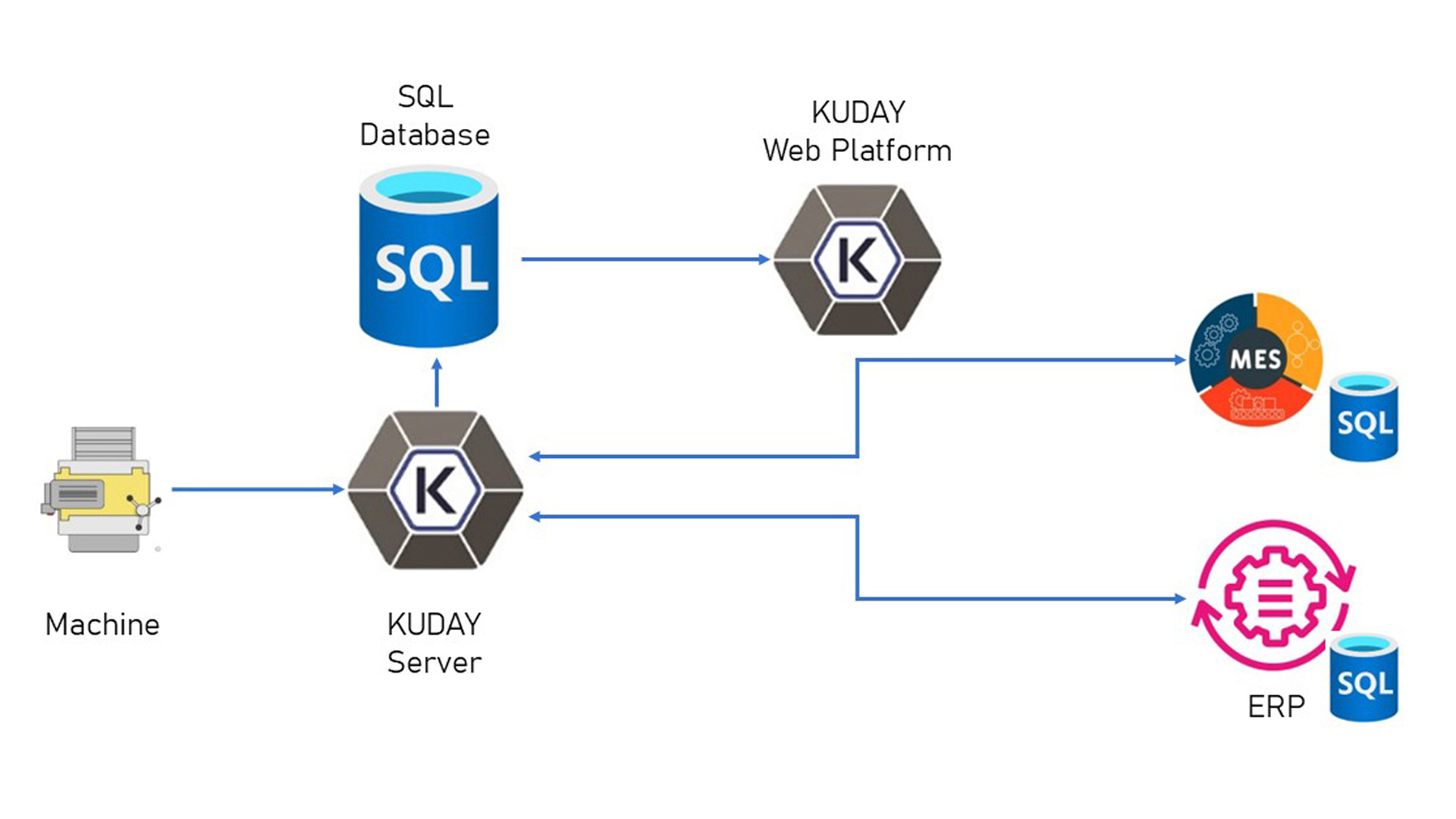

KUDAY SQL Server Module

The SQL Server module acts as a seamless bridge between industrial systems and enterprise databases. It enables the KUDAY platform to read, write, and synchronize data directly with Microsoft SQL Server, ensuring that production information, machine parameters, and event logs are safely stored and easily accessible.

In practical terms, this module allows automatic data transfer between the shop floor and the corporate IT layer - for example, pushing real-time process data into ERP or reporting systems, or retrieving set points and recipes for machines. By using the SQL Server module, organizations can unify their operational and business data into one reliable source of truth for analysis, reporting, and decision-making.

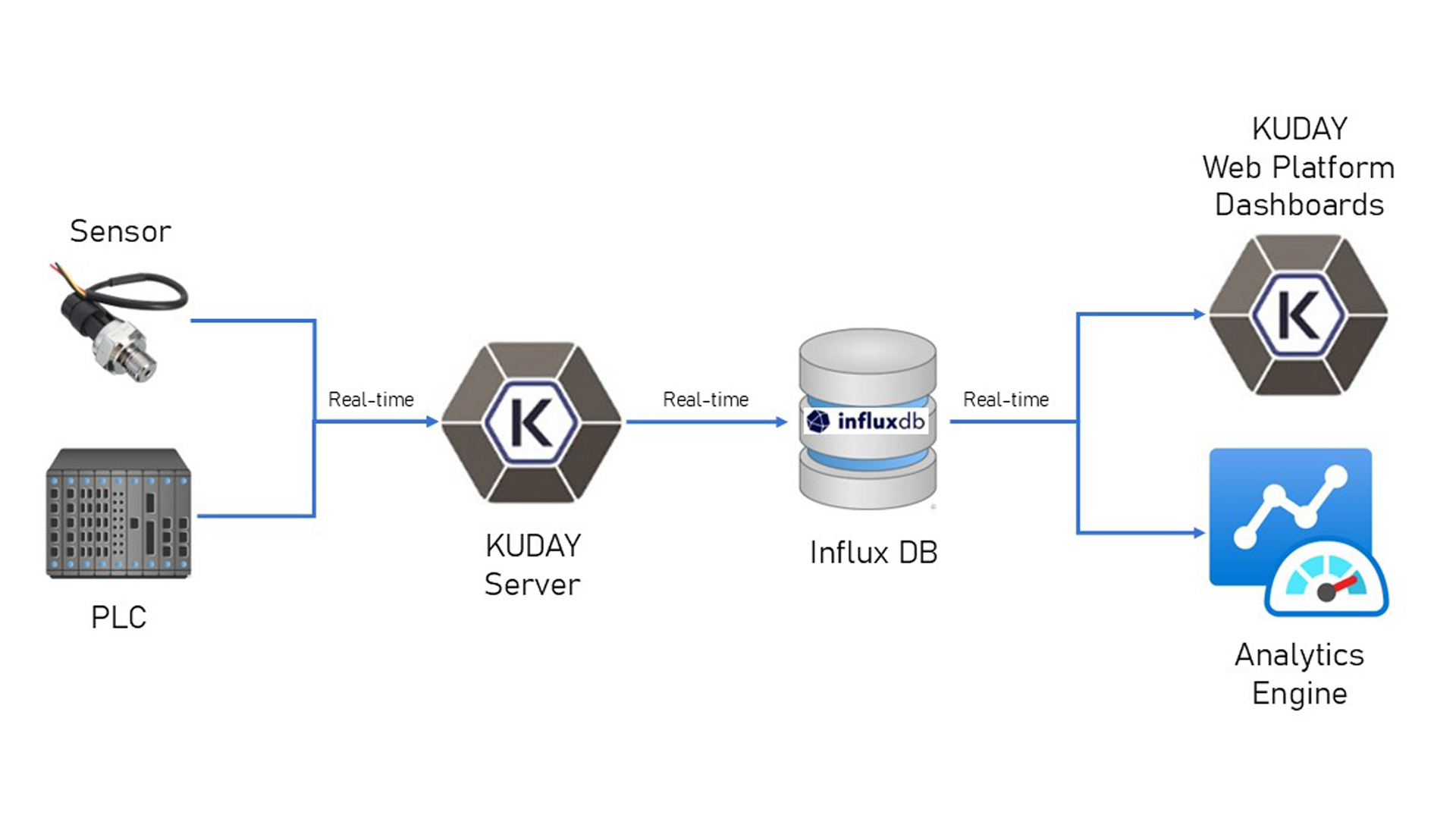

KUDAY InfluxDB Module

The InfluxDB module is designed for efficient storage and retrieval of time-series data - the kind of data that changes continuously over time, such as machine temperatures, pressures, or energy consumption values. This module connects KUDAY to InfluxDB databases, allowing real-time process data to be logged with high frequency and precision. It’s ideal for monitoring systems that require historical trends, predictive maintenance insights, or performance analytics.

By leveraging the InfluxDB module, users can visualize trends through the KUDAY Web Platform, compare performance over specific time intervals, and detect anomalies early. In short, it provides the foundation for building powerful dashboards, OEE calculations, and time-based process analysis.

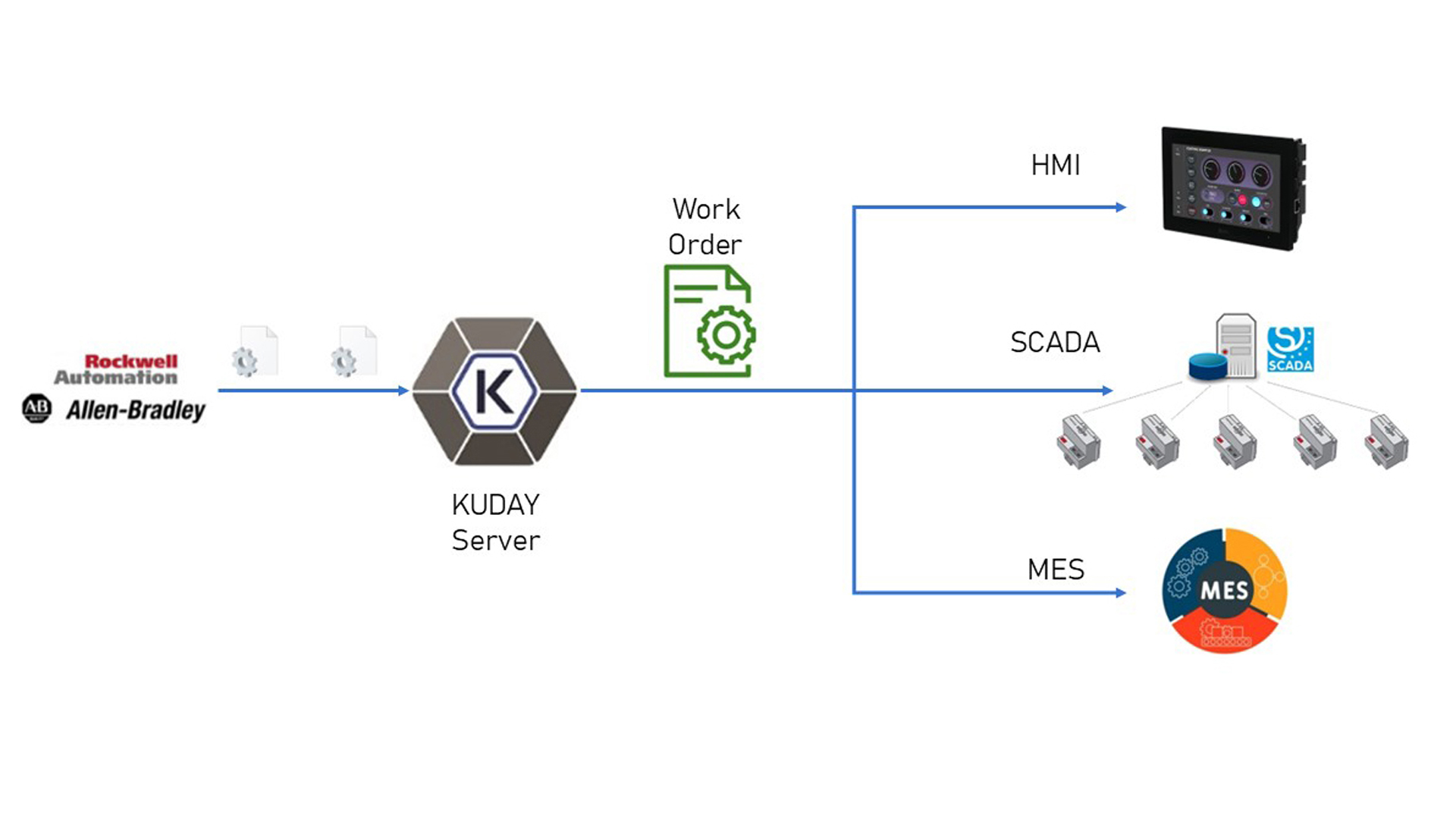

KUDAY Allen-Bradley PLC Module

The Allen-Bradley module enables direct and reliable communication between KUDAY and Allen-Bradley PLCs using Ethernet/IP and native Rockwell protocols.

This module allows real-time data collection from controllers such as CompactLogix and ControlLogix, supporting both read and write operations for process variables, alarms, and machine states.

By integrating Allen-Bradley equipment with KUDAY, production and maintenance teams gain centralized visibility of their operations - from equipment status and performance to critical process parameters.

The module eliminates the need for complex middleware or manual data transfer, ensuring smooth data synchronization between the shop floor and higher-level systems like MES or ERP. It’s ideal for facilities using Rockwell Automation infrastructure but aiming to unify their plant data in one scalable KUDAY ecosystem.

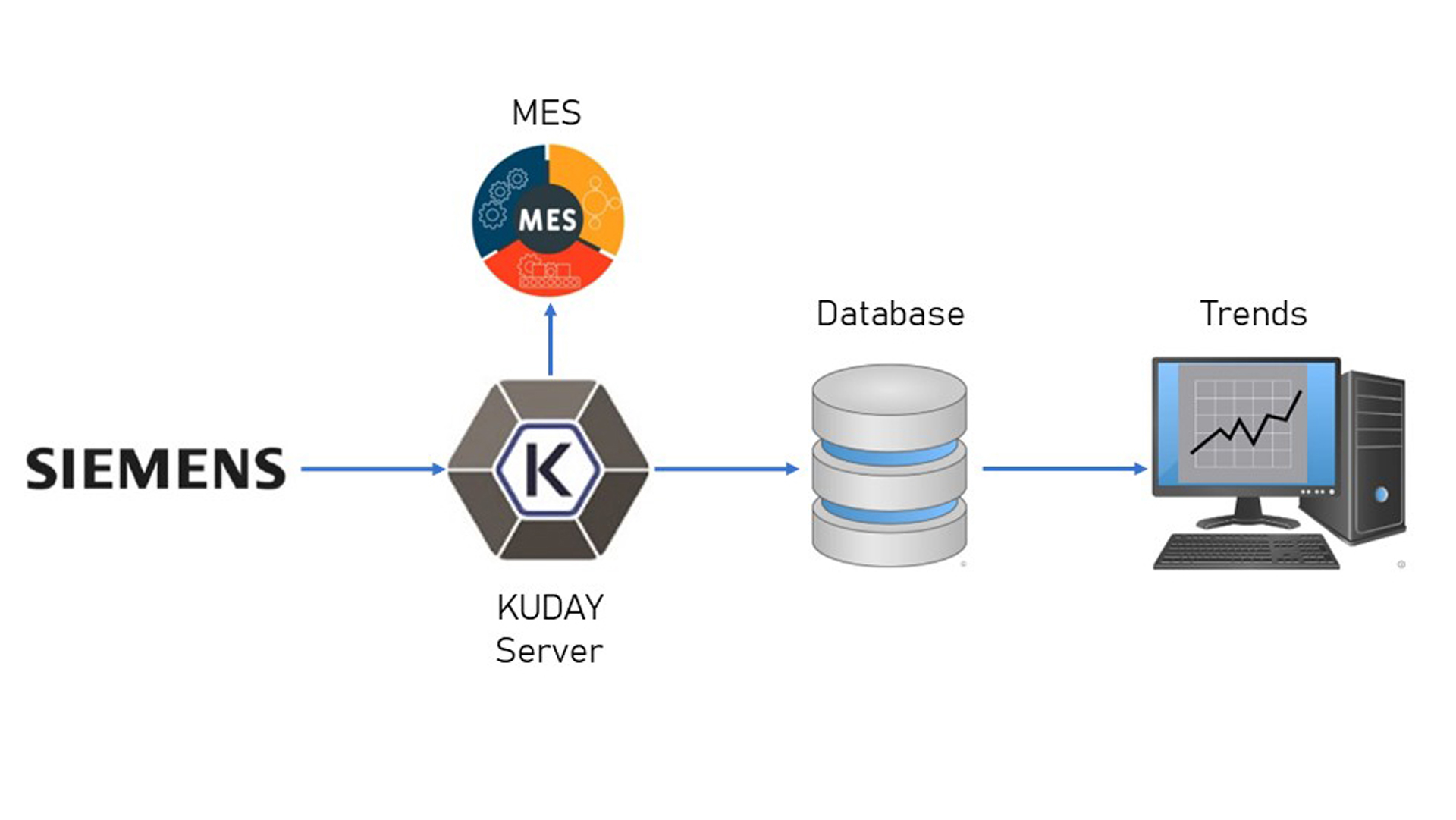

KUDAY Siemens PLC Module

The Siemens PLC module enables seamless communication between KUDAY and Siemens controllers, such as S7-1200, S7-1500, and S7-300 series, using the native S7 protocol or Profinet.

This module provides full data access for reading and writing process variables, alarms, and operational parameters directly from Siemens PLCs. It allows KUDAY to act as a central data hub — collecting machine data, visualizing it in dashboards, and enabling higher-level systems like MES or ERP to make informed, real-time decisions.

With this integration, production and maintenance teams can unify data from Siemens-based systems with other vendor PLCs through the same KUDAY platform.

The result is a simplified, vendor-agnostic data environment that improves interoperability, traceability, and control across the entire factory network.

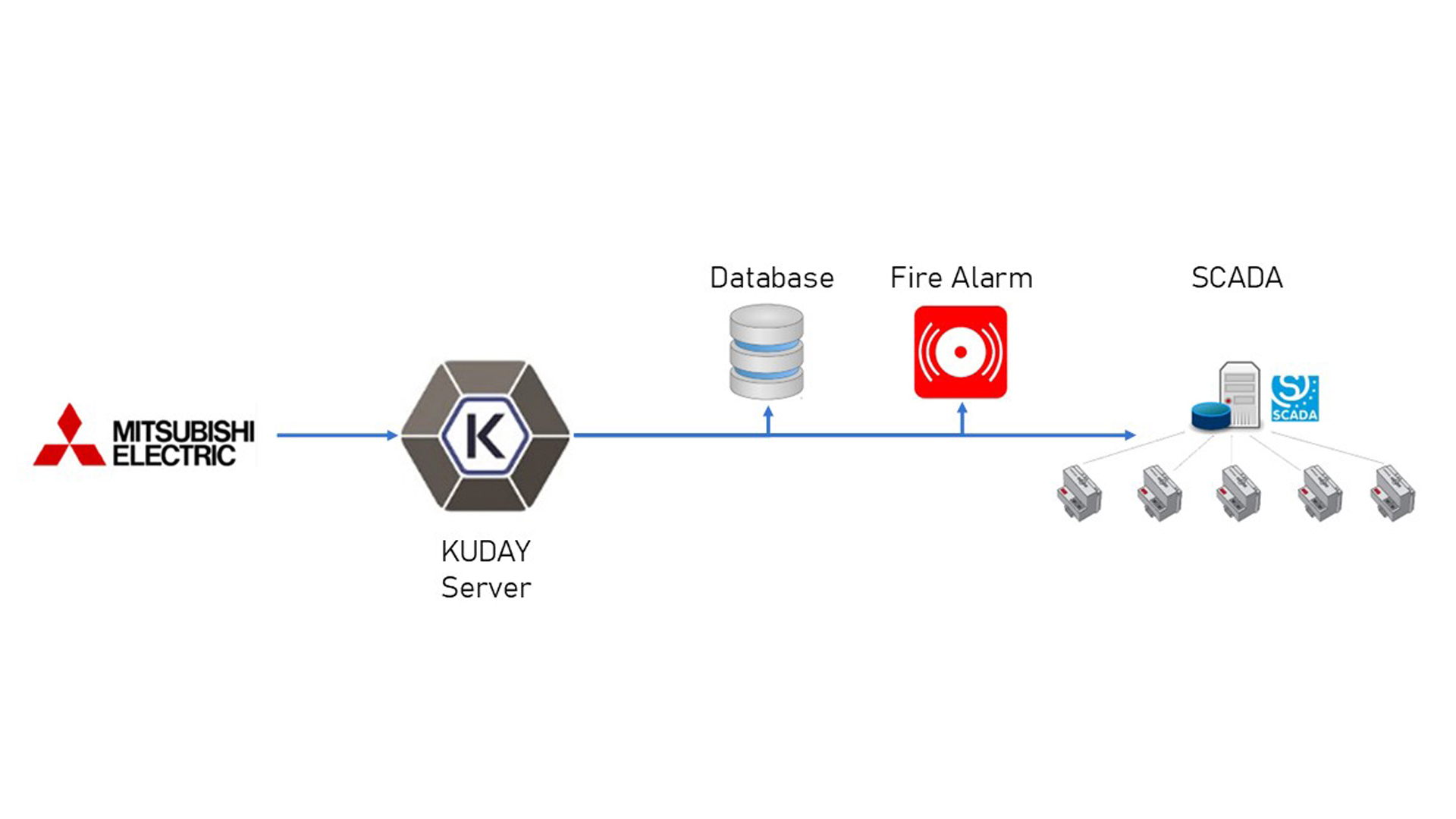

KUDAY Mitsubishi PLC Module

The Mitsubishi PLC module connects the KUDAY platform with Mitsubishi controllers, such as the FX, Q, and iQ-R series, through protocols like MC Protocol and Modbus TCP/RTU.

This module allows seamless data exchange between KUDAY and Mitsubishi PLCs - capturing key process parameters, alarms, and status signals from the production floor. Once collected, this information can be visualized in the KUDAY Web Platform for real-time monitoring, reporting, and analytics.

The integration makes it possible to unify Mitsubishi-based machines with other PLC brands in a single system. This ensures that even legacy or isolated equipment can become part of a centralized data network, helping factories improve production visibility, process efficiency, and maintenance responsiveness.

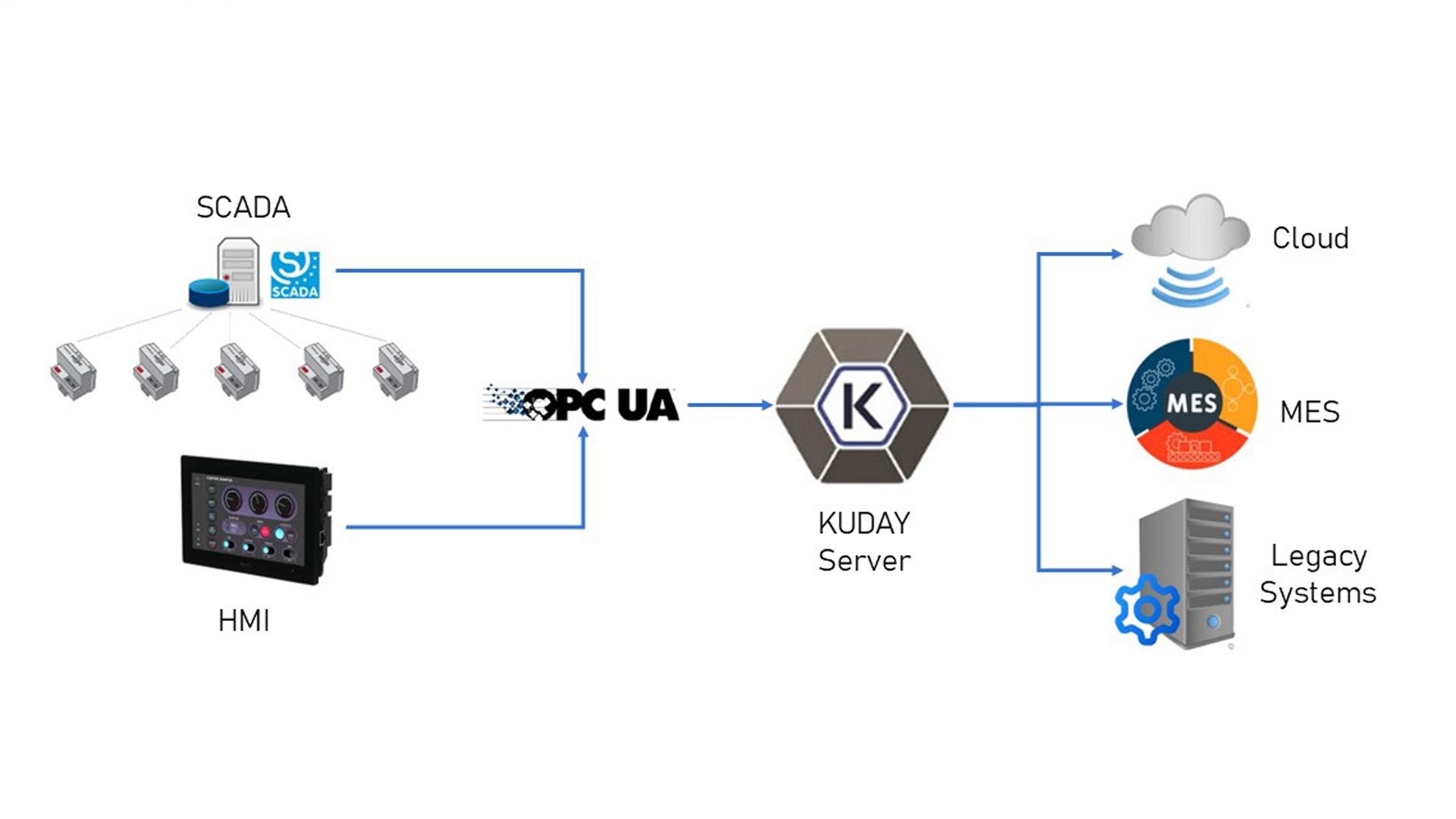

KUDAY OPC UA Server Module

The KUDAY OPC UA Server module acts as a powerful communication bridge, enabling secure, standardized data exchange between industrial equipment and higher-level applications such as MES (Manufacturing Execution Systems), ERP (Enterprise Resource Planning), and cloud analytics platforms.

This module exposes KUDAY’s internal process data, alarms, and variables through the OPC UA (Open Platform Communications Unified Architecture) protocol - one of the most widely adopted industrial standards for interoperability.

By using this module, any OPC UA-compatible client can connect to KUDAY, browse available tags, and read or write values in real time. This enables seamless system integration between different vendors and technologies, ensuring that automation, IT, and enterprise systems can communicate reliably within a unified data environment.

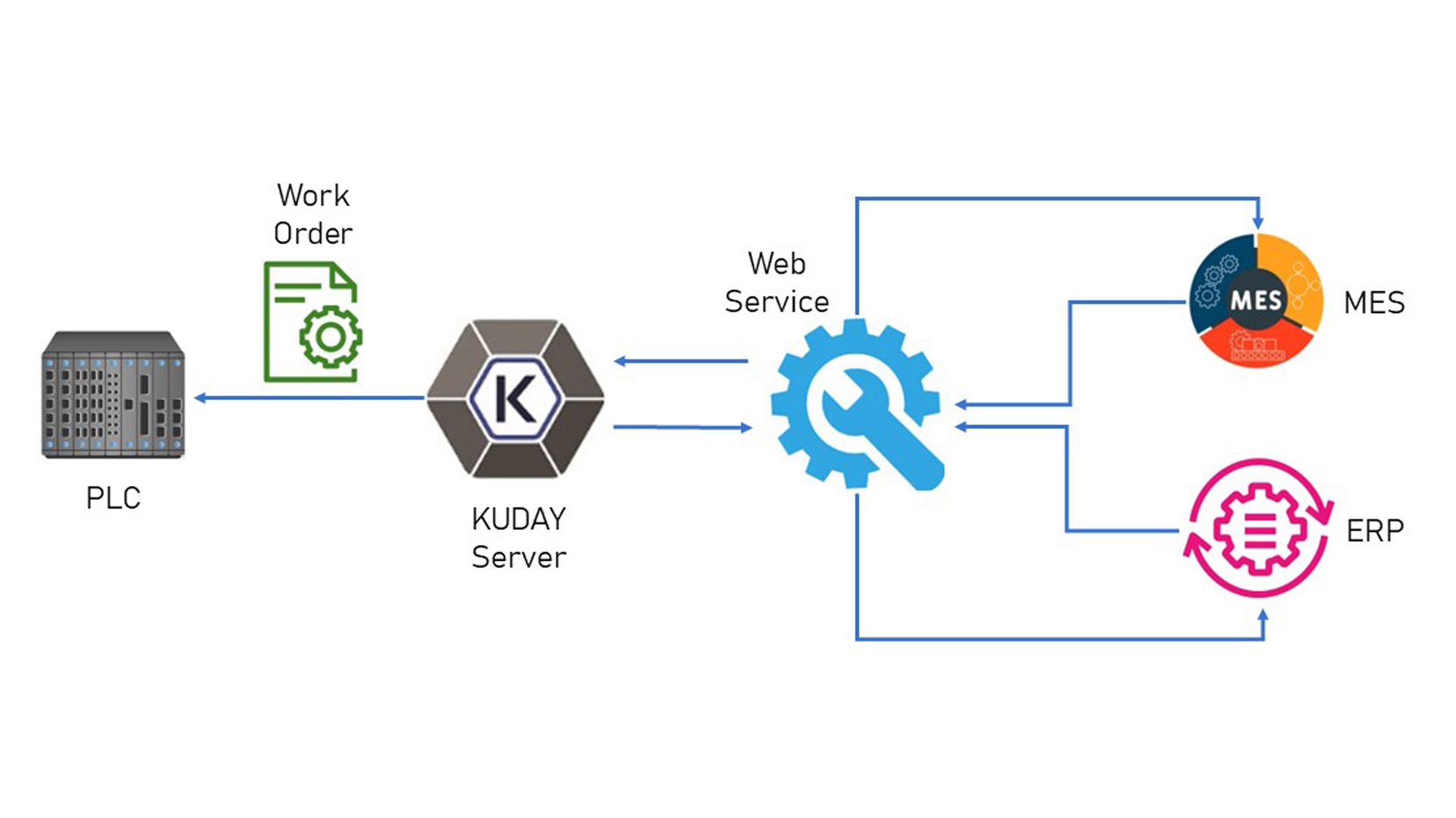

KUDAY Web Service Module

The KUDAY Web Service module enables seamless data exchange between KUDAY and web-based applications, APIs, or cloud platforms. It acts as a communication gateway, allowing real-time or scheduled data transmission using standard HTTP or HTTPS protocols.

This module is ideal for connecting industrial systems to external business applications, such as ERP, MES, or data visualization tools. It supports both sending and receiving structured data (e.g., JSON, XML), making it flexible for bidirectional communication between production-level devices and enterprise-level services.

Through the Web Service module, KUDAY can push process data, alarms, or production metrics to remote servers, or receive instructions and configurations from web-based systems. This creates an open ecosystem where industrial data can flow securely and efficiently between shop-floor operations and cloud or corporate environments - supporting IT/OT convergence and digital transformation initiatives.

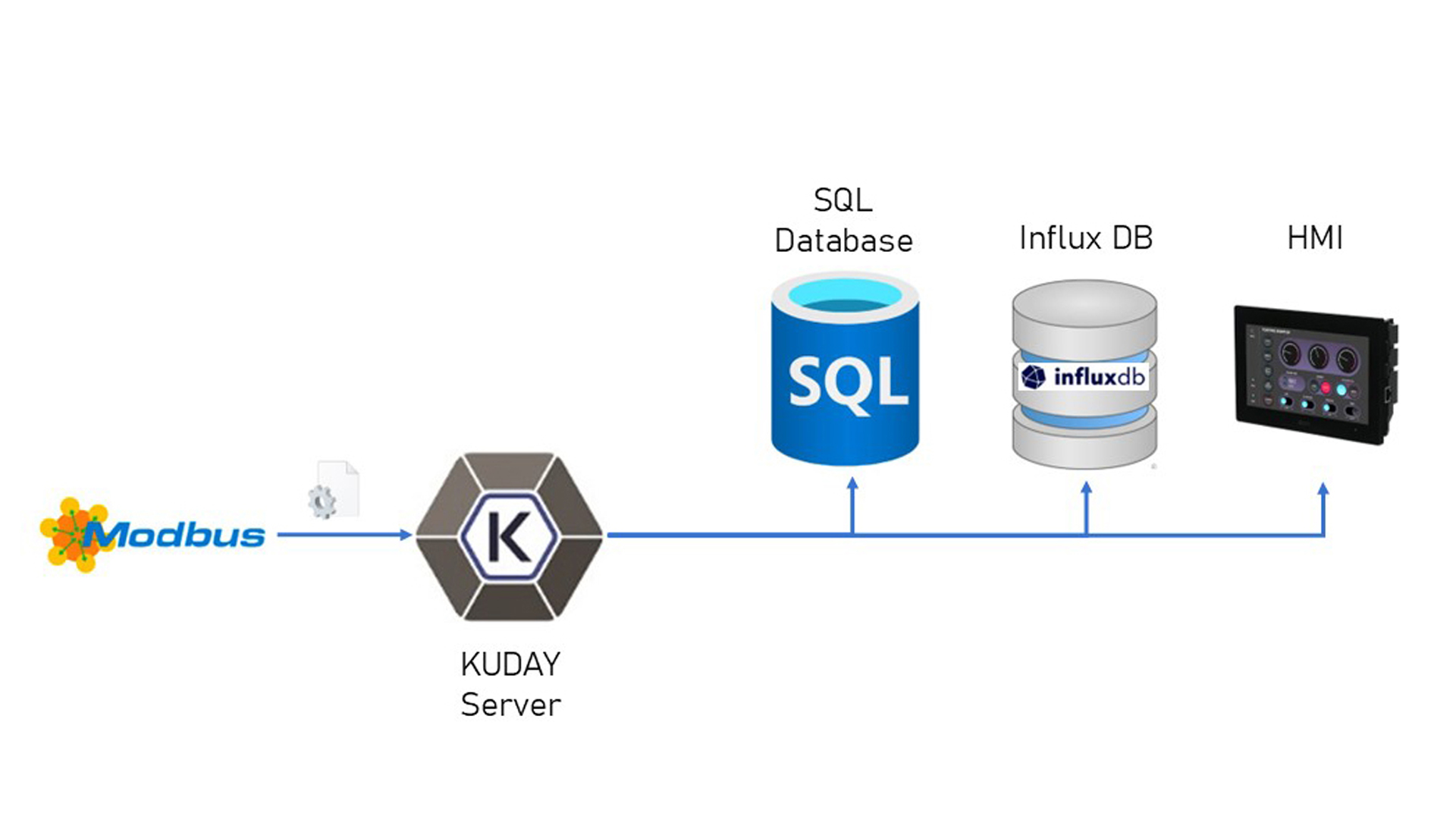

KUDAY Modbus Module

The Modbus module enables seamless communication between KUDAY and field devices such as PLCs, sensors, analyzers, and meters that use the Modbus RTU or Modbus TCP protocol.

As one of the most common industrial communication standards, Modbus allows KUDAY to read and write process variables - including temperature, flow, current, and pressure - directly from connected equipment.

With this module, data from multiple machines and controllers can be unified into a single KUDAY database for monitoring, reporting, or further analysis. It bridges the gap between legacy hardware and modern digital platforms, ensuring reliable data flow across mixed industrial environments.

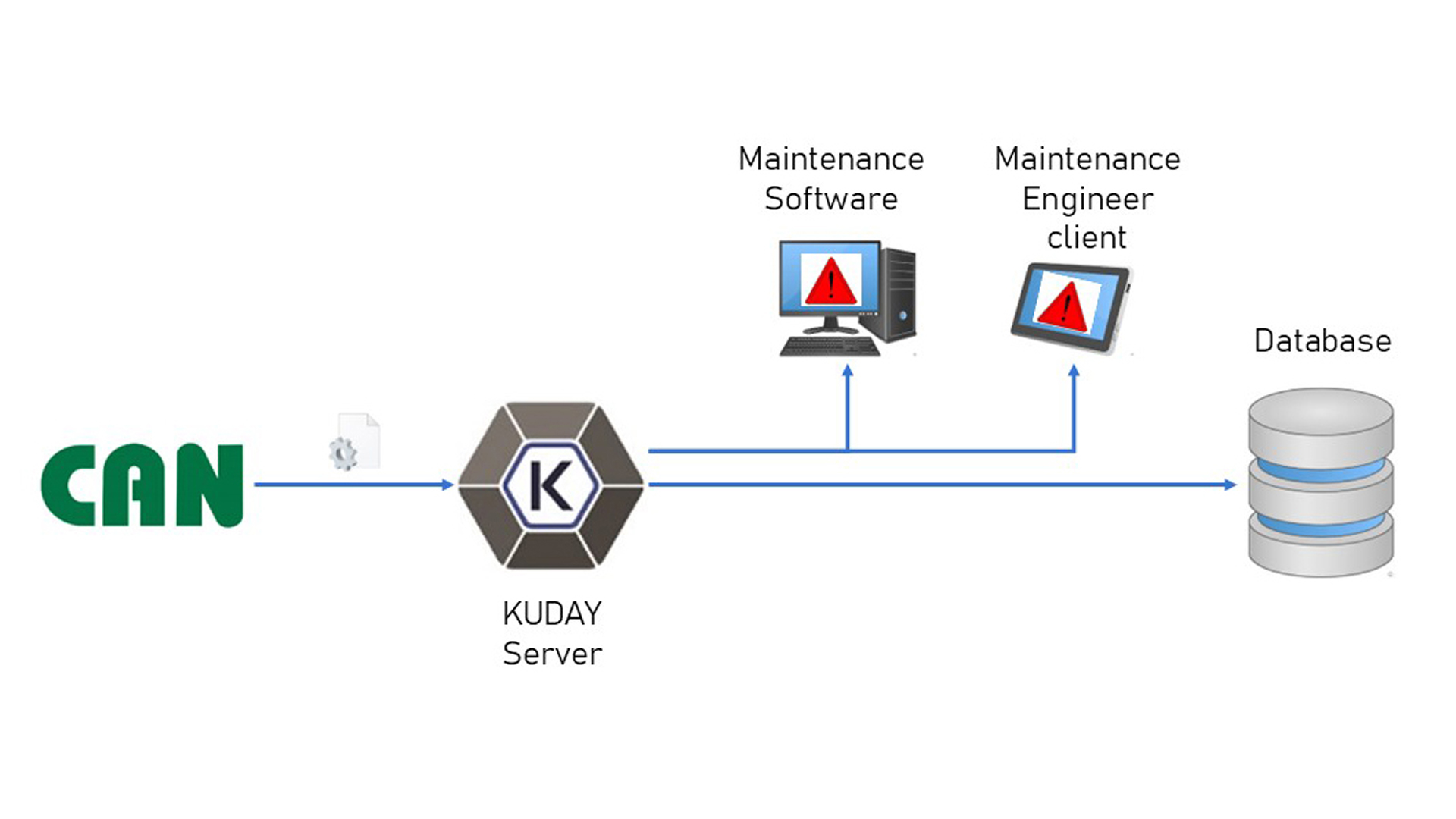

KUDAY CAN Bus Module

The KUDAY CAN Bus module enables seamless integration of industrial and mobile equipment that communicate via the CAN 2.0 or J1939 protocol, commonly used in vehicles, heavy machinery, and embedded control systems.

It captures real-time signals such as engine status, fault codes, operating hours, and sensor readings, then processes them within the KUDAY platform for use across operational workflows.

This allows critical machine data to be routed simultaneously to maintenance software for automated work order generation, to tablet-based engineering clients for on-the-go diagnostics, and to a central database for historical analysis, reporting, and traceability.

By bridging CAN-based devices with enterprise-level systems, the module transforms raw field data into structured, actionable information - enabling predictive maintenance, faster response times, and improved equipment reliability across mixed environments.

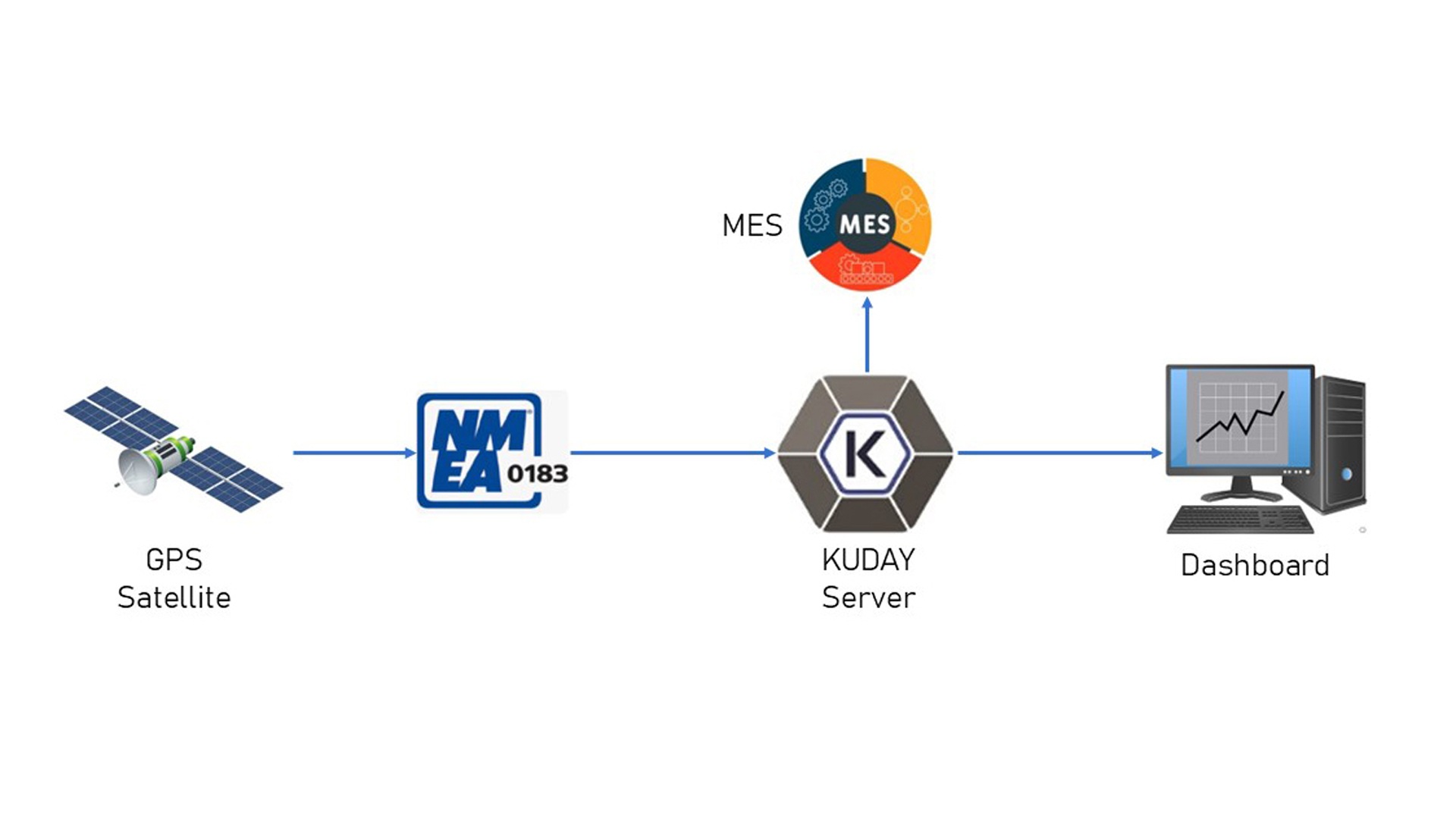

KUDAY NMEA0183 Module

Designed to work with devices that output data in the NMEA0183 format, this module captures real-time information such as position, speed, heading, and timestamp, then processes it within the KUDAY platform for use across various operational workflows.

It supports both TCP and UDP communication modes, allowing flexible deployment in fixed or mobile environments. Once integrated, the data can be routed to dashboards for live monitoring, logged for traceability, or used to trigger automated actions based on geographic or timing conditions.

By bridging specialized positioning equipment with standard industrial control systems, the NMEA0183 module extends KUDAY’s ability to unify diverse signal types - from machine inputs to mobile asset tracking - into a single, coherent data infrastructure.

KUDAY Socket Server Module

The KUDAY Socket Server module provides a flexible and efficient way to establish direct TCP/IP communication between KUDAY and various external systems, devices, or custom applications. Acting as a real-time data bridge, it allows bidirectional exchange of information without the need for complex middleware or proprietary interfaces.

This module is especially valuable in environments where machines, sensors, or third-party software need to continuously send or receive data from KUDAY using lightweight socket connections. Through configurable ports and message formats, users can easily integrate legacy equipment, test systems, or specialized applications into the wider KUDAY ecosystem.

By leveraging the Socket Server module, companies can achieve low-latency data transfer, enabling fast response times for automation, monitoring, or control scenarios. Whether used for sending production data, receiving control commands, or syncing with external analytics systems, this module ensures reliable and high-speed industrial communication tailored to modern smart factory requirements.

KUDAY Custom Modules

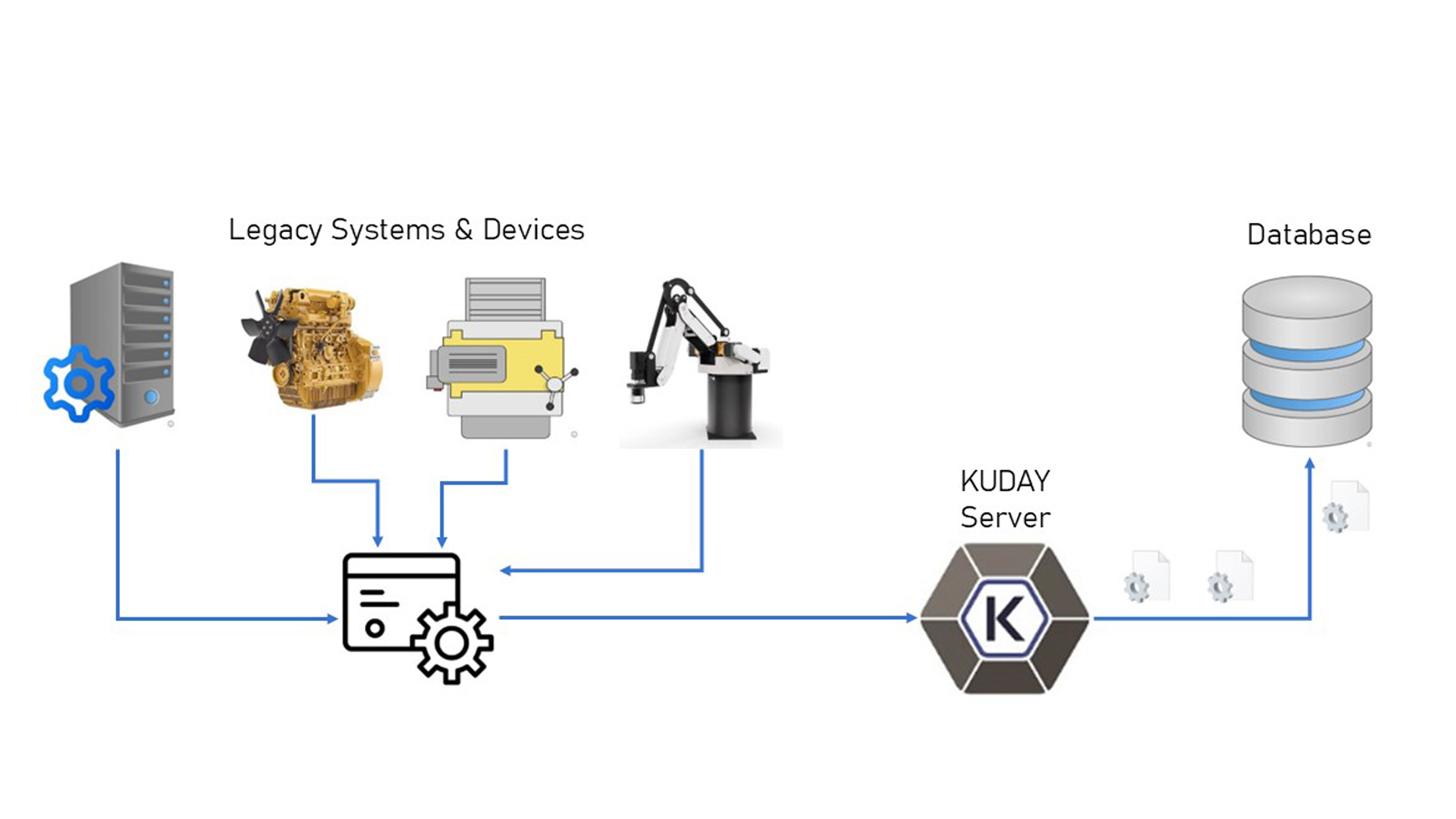

While standard satellite modules handle common protocols like Modbus, OPC UA, and PLC integration, many real-world environments require something more - which is where our custom modules come in.

We’ve developed numerous custom modules tailored to specific customer needs, enabling seamless connectivity with unique or proprietary equipment that wouldn’t otherwise integrate into a unified system. Whether it’s a legacy machine, a specialized sensor, or an automated conveyor system, we build dedicated modules that allow these components to exchange data with KUDAY in real time.

In this way, KUDAY becomes more than just a software platform - it evolves into a truly adaptable ecosystem, capable of bringing together all parts of your operation into a single, intelligent network. Data flows reliably from every corner of the facility into one central point, where it can be monitored, analyzed, and acted upon - making KUDAY the true center of your industrial data architecture.