In today's competitive industrial environment, doing more with less isn't optional - it's essential. At ARICANLI, our solutions help manufacturers and infrastructure operators enhance performance by eliminating inefficiencies, automating manual tasks, and gaining real-time insight into operations. We focus on turning raw data into actionable intelligence - so you can identify bottlenecks, reduce energy waste, improve OEE, and make faster, better decisions across all levels of your organization. No guesswork. No outdated reports. Just reliable, data-driven progress. Our approach combines deep field experience with proven technology: from smart dashboards and energy monitoring to full-scale digital transformation strategies - all built on our KUDAY platform and KRIO edge devices. Whether you're starting small or scaling up, we help you move from reactive operations to proactive optimization.

Smart Manufacturing

We enable true smart manufacturing by connecting machines, systems, and people through integrated automation.

Our solutions provide live visibility into production metrics, support predictive maintenance, and lay the foundation for scalable digitalization - without replacing existing equipment.

Digital Transformation

Digital transformation starts with solving real problems - not chasing technology.

We guide clients through the journey from paper-based workflows to connected, automated environments.

From initial assessment to implementation, we deliver practical, future-ready solutions that deliver fast ROI.

Energy Monitoring

Energy is one of the largest operational costs - yet often poorly understood.

We deploy precise monitoring systems that track consumption per machine, line, or facility in real time.

With accurate data, you can identify waste, optimize usage, and implement predictive maintenance strategies - reducing both cost and environmental impact.

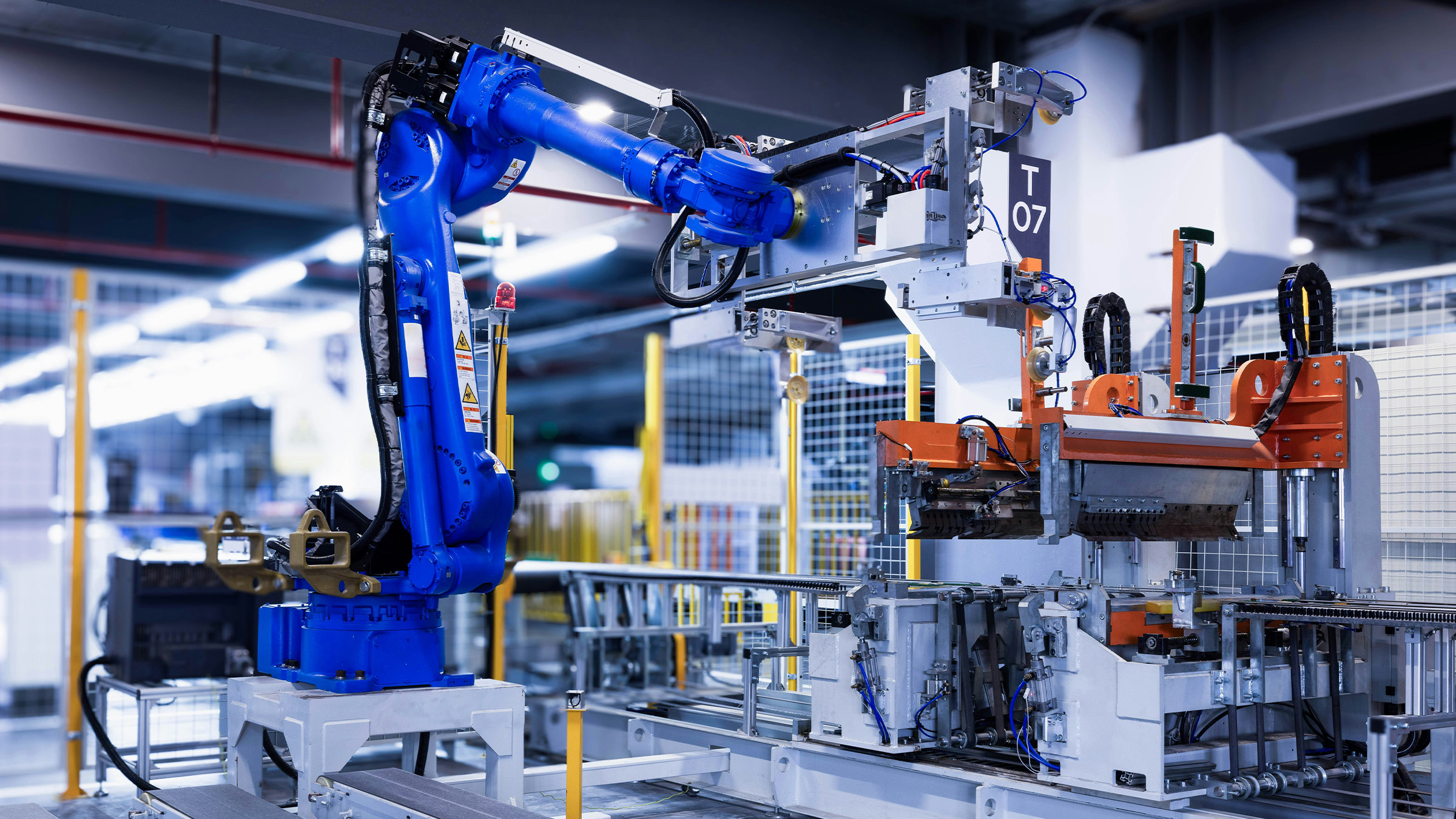

Production Automation

From semi-automated lines to fully integrated processes, we design and implement automation solutions that increase throughput, reduce errors, and improve consistency.

By connecting PLCs, sensors, and control logic, we help you achieve higher output with fewer resources - safely and reliably.

Ready to Improve your operations?

Smart Manufacturing in today world of 4.0 Industry aims to solve real problems with smart tools - connecting machines that already exist, collecting data that's already being generated, and turning it into actionable insights your team can use every day. Our solutions help you move beyond manual reporting, paper checklists, and isolated systems. We integrate PLCs, sensors, HMIs, and enterprise software into a unified ecosystem - so operators see live status, supervisors track performance in real time, and management makes decisions based on truth from the shop floor. No rip-and-replace. No black-box promises. Just reliable, incremental progress toward a more intelligent operation.

The Reality of Smart Manufacturing Today

At ARICANLI, we see smart manufacturing as practical digital transformation: solving real problems with reliable technology - from reducing scrap rates to eliminating manual reporting, from tracking OEE per shift to enabling faster changeovers.

It starts not with big investments, but with better use of what you already have - machines that generate data, operators who know the process, and engineers who want actionable insights.

Our role is to connect these elements into a unified system - so information flows freely, decisions are faster, and improvements become measurable.

Key Deliverables

Ready to make your factory smarter - one step at a time?

Digital transformation in modern manufacturing at its core is meant to connect machines to people, turning raw data into insight, and replacing manual work with smart, reliable automation.

At ARICANLI, we help manufacturers and industrial operators take practical steps toward smarter operations — starting with the systems they already have.

We enable real-time visibility into production, automate reporting and quality checks, and integrate shop floor data directly with ERP and MES platforms. Our solutions are built on proven tools like the KUDAY platform and KRIO edge devices, so you get fast results without disruption.

No overhauls. No guesswork. Just measurable improvements in efficiency, traceability, and control — one step at a time.

We help manufacturers and infrastructure operators evolve from legacy systems to smart, connected environments — turning data into decisions, machines into insights, and operations into competitive advantage.

How We Deliver Results

Full-Stack Expertise: From PLCs and KRIO edge devices to KUDAY software and ERP integrations, we handle every layer of the stack — hardware, software, networks, and user workflows.

Customized Roadmaps: No two factories are alike. We build phased implementation plans that fit your budget, timeline, and operational rhythm — starting small and scaling fast.

Change Management Support: We work closely with your teams — engineers, operators, IT, and management — to ensure smooth adoption and long-term success.

Continuous Improvement: Our solutions aren’t static. We monitor performance, gather feedback, and iterate — helping you stay ahead of the curve.

Ready to Begin Your Digital Transformation Journey?

In industrial operations, energy is one of the largest - and often least understood - expenses. Without accurate data, it's impossible to know where power, gas, or water is being wasted, when equipment starts consuming abnormally, or how much each machine contributes to overall usage.

At ARICANLI, our Energy Monitoring solutions provide real-time tracking of electricity, natural gas, water, temperature, and pressure across your facility - directly from existing meters, sensors, and PLCs. We connect these devices into a centralized system that logs, visualizes, and analyzes consumption patterns - so you can identify waste, optimize performance, and act before small issues become costly failures.

No more estimates. No more spreadsheets. Just reliable, actionable data.

Why Monitor Your Energy Consumption?

Uncontrolled consumption is one of the largest hidden costs in manufacturing.

Without accurate data, it's impossible to:

- Identify waste or inefficiencies

- Calculate production costs per product

- Validate utility bills

- Meet internal efficiency targets or compliance requirements

At ARICANLI, we design energy monitoring systems that go beyond simple meter reading. Our solutions capture contextual data - tied to shifts, batches, or machine states - turning raw consumption numbers into actionable insights.

Whether you're looking to reduce peak load, track usage by department, or set up alerts for abnormal spikes, our approach helps you make smarter decisions - based on real data, not estimates.

How we do it?

Using KRIO edge devices and the KUDAY platform, we integrate with a wide range of measurement hardware:

- Electricity meters (via Modbus, pulse outputs, or analog signals)

- Water and gas meters (pulse or digital communication)

- Temperature and pressure sensors

- Flow meters and environmental probes

We are working with various brands and protocols, in order to connect and centralize energy consumption data.

Since all KUDAY Modules are developed in-house, we can adapt quickly to unique site requirements.

What We Deliver

Ready to gain full visibility into your facility's resource use?

At ARICANLI, we help manufacturers get more from their equipment by automating repetitive tasks, synchronizing processes, and reducing reliance on manual intervention.

Our solutions are designed to increase output, improve product consistency, and reduce human error - without requiring full machine replacements or costly overhauls.

We work directly with PLCs, sensors, HMIs, and control logic to build intelligent systems that respond to real-time conditions - starting small and scaling fast based on your operational needs.

No templates. No black boxes. Just practical automation built around how your factory really works.

What is Production Automation?

Production automation goes beyond monitoring - it's about actively controlling how machines operate.

From simple start-stop sequences to complex interlocks between conveyors, robots, and quality checks, automation ensures processes run safely, efficiently, and without unnecessary human intervention.

The biggest challenge in automation is creating communication between different types of machines, different manufacturers into one system where processes are defined, precise, and no data is lost.